一、概述/ Summary:

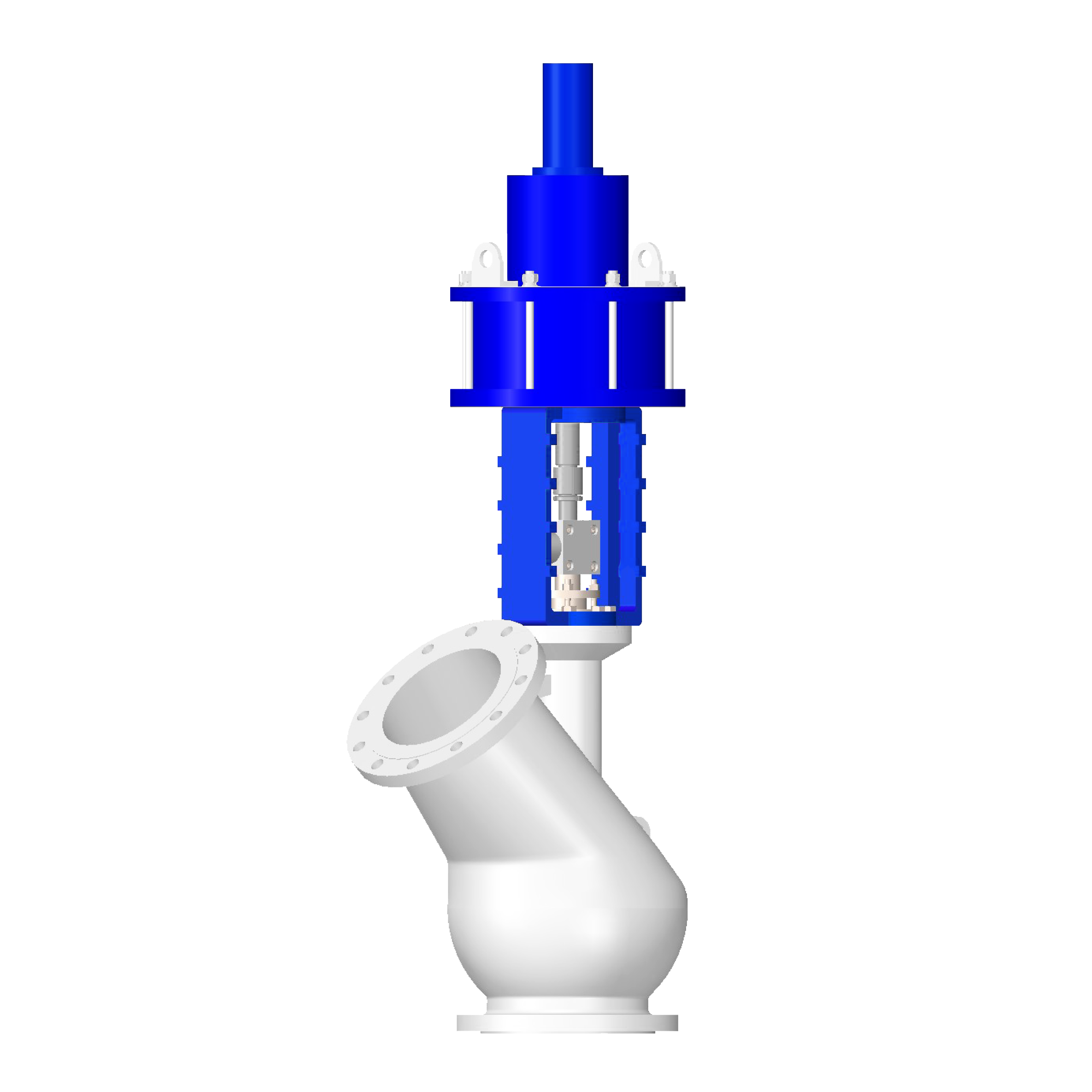

Y型放料角閥主要用于反應釜,儲罐和其它容器的底部排料、放料、取樣和無死區關斷操作。主要分為:上展式放料角閥、下展式放料角閥。上展式用于有攪拌器(除框式錨式)的反應釜放料;而下展式用于框式錨式攪拌器的反應釜放料。上展式放料角閥為閥瓣向上運動閥門打開,打開時閥門需克服介質作用力,打開時較關閉力矩大。下展式放料角閥為閥瓣(柱塞)向下運動閥門打開,打開時運動方向與介質作用力相同,因而打開時較關閉力矩小。在化工、石油、冶金、制藥、農藥、染料、食品加工等行業廣泛使用。各種操作方式,例如,手動,氣動,電動,液動等。

Y-type discharge angle valve is mainly used for bottom discharge, discharge, sampling and dead-zone shutdown operation of reactor, storage tank and other vessels. It is mainly divided into: up-spread discharging angle valve and down-spread discharging angle valve. Upward expansion type is used for discharging of reaction kettle with agitator (except frame anchor type); The downward expansion type is used for discharging the reaction kettle of the frame-type anchor agitator. The up-spread discharge angle valve is the valve with upward movement of the valve disc. When opening, the valve needs to overcome the medium force, and the opening torque is greater than the closing torque. The downward spreading discharge angle valve is the valve with downward movement of the valve disc (plunger). When opening, the movement direction is the same as the medium force, so the opening torque is smaller than the closing torque. It is widely used in chemical, petroleum, metallurgy, pharmaceuticals, pesticides, dyes, food processing and other industries. Various operation modes, such as manual, pneumatic, electric, hydraulic, etc.

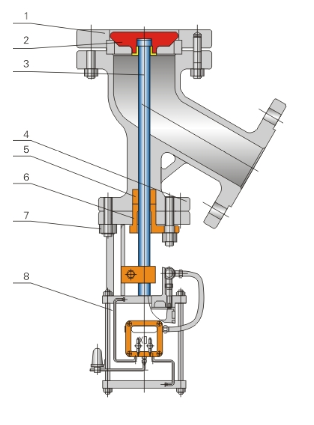

二、結構和材質/ Structure And Material:

| 序 | 零部件/Parts Name | 材質/Material |

| 1 | 閥體/Body | WCB/CF8 |

| 2 | 閥瓣/Disc | 304/A105+13Cr |

| 3 | 閥桿/Stem | 304/2Cr13 |

| 4 | 支架/Yoke | CF8/WCB |

| 5 | 填料/Packing | PTFE/石墨 |

| 6 | 填料壓蓋/Gland | CF8/WCB |

| 7 | 螺栓/Bolt | A193B8/35CrMo |

| 8 | 執行機構/Actuator | 組合件 |

三、主要技術性能/ Main technical performance:

| 序號 | 類別/Type | 參數和性能/Parameters and performance |

| 1 | 公稱通徑/ Body size | DN25—DN600/1”-24” |

| 2 | 公稱壓力/ Disc form | PN10-PN25 |

| 3 | 適用介質/Applicable media | 泥漿,煤漿,灰渣、粉料、顆粒等/Mud, coal slurry, ash, etc |

| 4 | 適用溫度/Temperature Range | -29-425°C |

| 5 | 泄漏等級/Seat Leakage | ANSI CLASS Ⅴ或Ⅵ級 |

| 6 | 連接方式/Body connections | 法蘭連接RF、MF、RTJ等/ Flange connection RF, MF, RTJ, etc |

| 7 | 結構形式/Construction style | 角式/Angular type |

| 8 | 驅動方式/Operation | 手動、氣動、電動、液動/Manual, pneumatic, electric and hydraulic |

| 9 | 設計制造標準/Design and Manufacture | GB/T-12236 |

| 10 | 結構長度/Face to Face Dimension | HG/T3704-2003、GB/T 12221、ASME-B16.10 |

| 11 | 法蘭尺寸/Flange Connection Dimension | HG20592-2009、ANSI B16.5 |

| 12 | 檢測和試驗/Test and Inspection | GB/T13927-2008、API598 |

四、特點/ Characteristic:

4.1、耐沖刷、性能穩定可靠。閥瓣閥座密封面采用耐沖刷、耐腐蝕材料,并進行硬化處理,使表面硬度達到HRC48~60,具有高耐磨、耐腐蝕的性能,密封副采用線密封,保證密封的可靠性。Erosion resistance, stable and reliable performance. The sealing surface of the valve disc and valve seat is made of wash-resistant and corrosion-resistant materials and hardened to make the surface hardness reach HRC48~60, with high wear resistance and corrosion resistance. The sealing pair is sealed with wire to ensure the reliability of sealing.

4.2、有快開和快關功能設計。采用短行程閥瓣的設計,在提高閥桿的穩定性的同時,也能快速的實現閥門的全開與全關。It has fast opening and fast closing function design. The design of short-stroke valve disc can not only improve the stability of the valve stem, but also quickly realize the full

opening and full closing of the valve.

4.3、密封可靠零外漏。填料函采用雙組多層的復合填料設計,下層密封材料是柔性石墨環,同時起到一定的防塵作用,中間有一個隔環,隔環中可存儲潤滑脂,上層為增強聚四氟乙烯的V型成形填料或柔性石墨環,根據工作溫度來確定,填料的松緊可通過填料壓蓋的螺栓來調整。Reliable sealing and zero leakage. The stuffing box is designed with double-group and multi-layer composite packing. The lower sealing material is flexible graphite ring, which also plays a certain role in dust prevention. There is a spacer ring in the middle, which can store grease. The upper layer is reinforced PTFE V-shaped packing or flexible graphite ring, which is determined according to the working temperature. The tightness of the packing

can be adjusted by the bolts of the packing gland.

4.4、選材和工藝升級,壽命有保障。閥桿采用高強度、耐腐蝕的合金材料,與介質接觸部位可進行了表面硬化處理,更耐磨,抗腐蝕。Material selection and process upgrading ensure the service life. The valve rod is made of high-strength and corrosion-resistant alloy material. The contact part with the medium

can be subject to surface hardening treatment, which is more wear-resistant and corrosion-resistant.

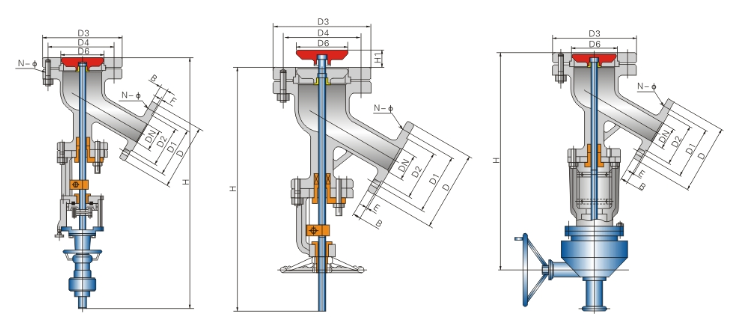

五、外形及連接尺寸/ Shape connection size

5.1上展式:

| 口徑(DN) | 連接尺寸和重量 | |||||||

| D | D1 | D2 | N-φ | D3 | D4 | D6 | Kg | |

| 25 | 115 | 85 | 68 | 4-14 | 115 | 85 | 40 | 10 |

| 32 | 140 | 100 | 78 | 4-18 | 140 | 100 | 45 | 13 |

| 40 | 150 | 110 | 88 | 4-18 | 150 | 110 | 60 | 15 |

| 50 | 165 | 125 | 102 | 4-18 | 165 | 125 | 70 | 22 |

| 65 | 185 | 145 | 122 | 8-18 | 185 | 145 | 85 | 31 |

| 80 | 200 | 160 | 138 | 8-18 | 200 | 160 | 95 | 38 |

| 100 | 220 | 180 | 158 | 8-18 | 220 | 180 | 130 | 52 |

| 125 | 250 | 210 | 188 | 8-18 | 250 | 210 | 140 | 81 |

| 150 | 285 | 240 | 212 | 8-22 | 285 | 240 | 165 | 110 |

| 200 | 340 | 295 | 268 | 12-22 | 340 | 295 | 230 | 156 |

| 250 | 405 | 355 | 320 | 12-26 | 405 | 355 | 275 | 230 |

| 300 | 460 | 410 | 378 | 12-26 | 460 | 410 | 325 | 305 |

| 350 | 520 | 470 | 428 | 16-26 | 520 | 470 | 375 | 388 |

| 400 | 580 | 525 | 490 | 16-30 | 580 | 525 | 425 | 495 |

| 450 | 640 | 585 | 550 | 20-30 | 640 | 585 | 475 | 610 |

| 500 | 715 | 650 | 610 | 20-33 | 715 | 650 | 525 | 730 |

| 600 | 840 | 770 | 725 | 20-36 | 840 | 770 | 625 | 980 |

5.2下展式:

口徑(DN) | 連接尺寸和重量 | |||||||

D | D1 | D2 | N-φ | D3 | D4 | D6 | Kg | |

25 | 115 | 85 | 68 | 4-14 | 140 | 100 | 32 | 8.5 |

32 | 140 | 100 | 78 | 4-18 | 150 | 110 | 40 | 10 |

40 | 150 | 110 | 88 | 4-18 | 165 | 125 | 50 | 13 |

50 | 165 | 125 | 102 | 4-18 | 185 | 145 | 65 | 15 |

65 | 185 | 145 | 122 | 8-18 | 200 | 160 | 80 | 22 |

80 | 200 | 160 | 138 | 8-18 | 220 | 180 | 90 | 31 |

100 | 220 | 180 | 158 | 8-18 | 250 | 210 | 110 | 44 |

125 | 250 | 210 | 188 | 8-18 | 285 | 240 | 135 | 71 |

150 | 285 | 240 | 212 | 8-22 | 340 | 295 | 165 | 100 |

200 | 340 | 295 | 268 | 12-22 | 405 | 355 | 215 | 146 |

250 | 405 | 355 | 320 | 12-26 | 460 | 410 | 275 | 220 |

300 | 460 | 410 | 378 | 12-26 | 520 | 470 | 325 | 295 |

350 | 520 | 470 | 428 | 16-26 | 580 | 525 | 375 | 378 |

400 | 580 | 525 | 490 | 16-30 | 640 | 585 | 425 | 482 |

450 | 640 | 585 | 550 | 20-30 | 715 | 650 | 475 | 590 |

500 | 715 | 650 | 610 | 20-33 | 840 | 770 | 525 | 710 |

600 | 840 | 770 | 725 | 20-36 | 910 | 840 | 625 | 950 |

備注:

1、表中標注的重量會因為執行機構的不同會有偏差; The weight indicated in the table will vary due to different actuators;

2、表中未列舉尺寸和未明事項請聯系并以我司技術數據為準,也可根據用戶需求具體定制。Please contact us for the sizes and unspecified items not listed in the table, and the technical data of our company shall prevail, or they can be customized according to user needs.

六、型號編制/ Model Etablishment:

HD | 8 | E | 88 | H | - | 16 | S | - | 150 | A |

廠家 代號 | 閥門 類型 | 驅動 形式 | 閥門 代號 | 密封 形式 | - | 公稱壓力 | 閥體材質 | - | 出口通徑 | 閥瓣形式 |

HD/ 漢德 | 8/直行程系列 | P/氣動 HY/液動 A/氣液 E/電動 | 88/放料 角閥 | H/硬密封 X/軟密封 H(X)/軟硬密封 | MPa或(磅) | C/WCB S/CF3/CF3M S/CF8/CF8M I/Incoloy 825 D/SAF2507 | mm或寸 | A/上展式 B/下展式 |

示例:如選擇口徑為DN150,閥體材質為CF8,硬密封閥座,電動執行機構,公稱壓力為PN16,上展式閥瓣的漢德Y型放料角閥的產品編號為:HD8E88H-16S-150A。

七、訂貨須知/ Pre Oder Iformation

1、公稱通徑;公稱壓力;法蘭連接形式;

2、流量特性;供氣壓力;

3、閥作用形式,故障位置;

4、附件要求(定位器、減壓閥、手輪等)

5、正常流量和要求最大流量;

6、介質名稱、溫度、比重、閥前和閥后壓力(對應最大or最小流量時的)

7、介質粘度,是否有懸濁液,濃度,顆粒大小);

8、或提供詳細數據表。

1,Nominal diameter; nominal pressure; flange connection;

2,flow characteristics, supply pressure;

3,valve action form, fault location;

4,accessories requirements (positioner, relief valve, hand wheel, etc.)

5,normal flow and required maximum flow;

6,medium name, temperature, specific gravity, pressure (corresponding to the maximum or minimum flow)

7,whether the suspension, medium viscosity, concentration, particle size);

8,or provide detailed data sheet.